Technical Specifications

Table: 630 mm x 450 mm

X: 370 mm Y: 270 mm Z: 220 mm

There are additional secondary benefits with the use of an oil di-electric fluid that help to improve work piece quality. The lower power levels help to produce lower levels of HAZ and Recast to a point to where they are virtually undetectable. Unlike deionized water, the oil di-electric fluid is chemically neutral, so it completely eliminates oxidation, meaning that steel work pieces will never rust while in the machine. Oil also protects synthetic materials such as carbide and PCD diamond, and eliminates the oxidation corrosion of these materials binder composition, such as cobalt depletion of carbide, and preserves the material integrity to provide dramatic increases in component functional life.

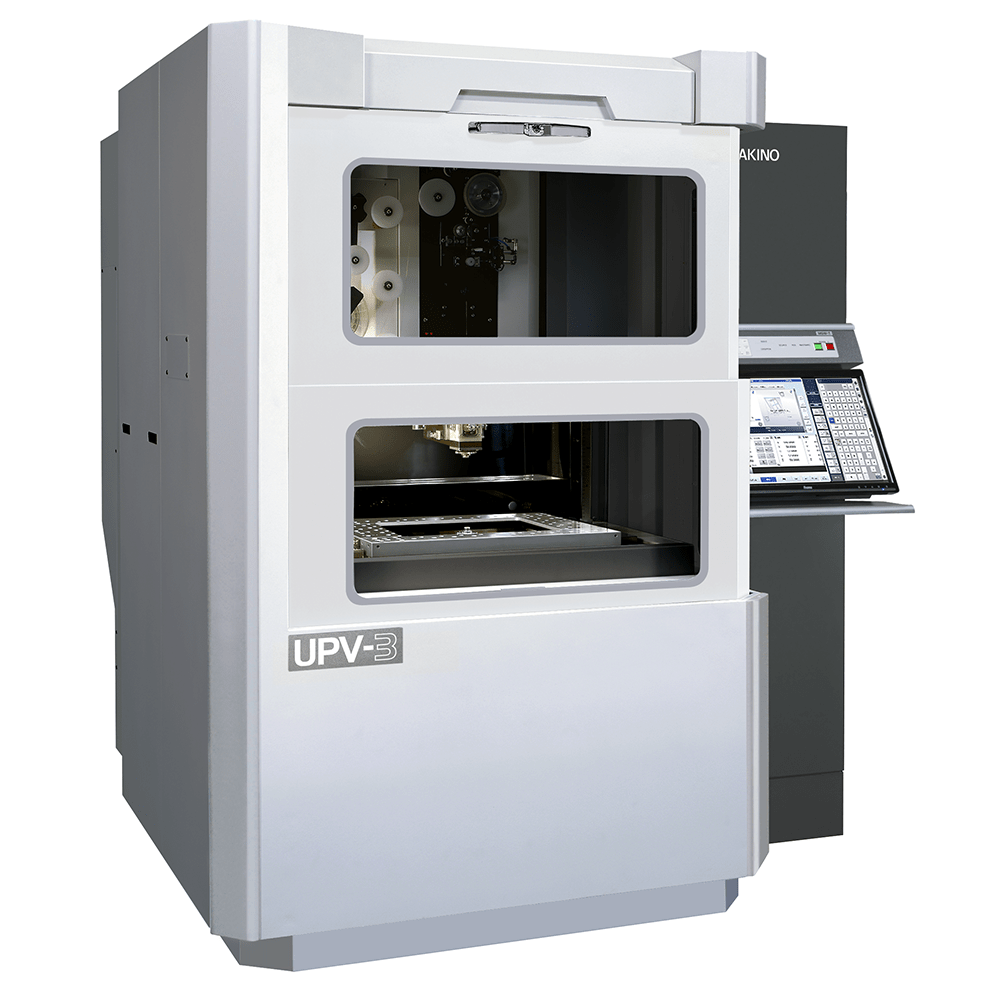

Operational access to the work zone is excellent with the 3-sided rise and fall work tank design, as this simplifies loading and setup of the work piece while also minimizes automation requirements. User-friendliness and productivity are hallmarks of the UPV-3 machine with the Hyper i control system. The modern high definition wide 24” class touch screen utilizes Pinch/Swipe/Drag operation similar to smartphones that make operation extremely easy and straightforward. The Hyper-i control also features a standard advanced Handbox, on-board electronic manuals, advanced E-Tech Doctor function, and video training tutorials that empower the operator with everything they need to be productive right at their fingertips.

The UPV-3 is an ideal machine for ultra-precision applications such as precision stamping and fine-blanking components, and can be equipped with an optional integrated 3D Setup Probe and Rotary Table, which are ideal for Cutting Tool Insert manufacturing. The UPV-3 is also standard with safety equipment such as an integrated Fire Suppression system for reliable extended unattended operation.