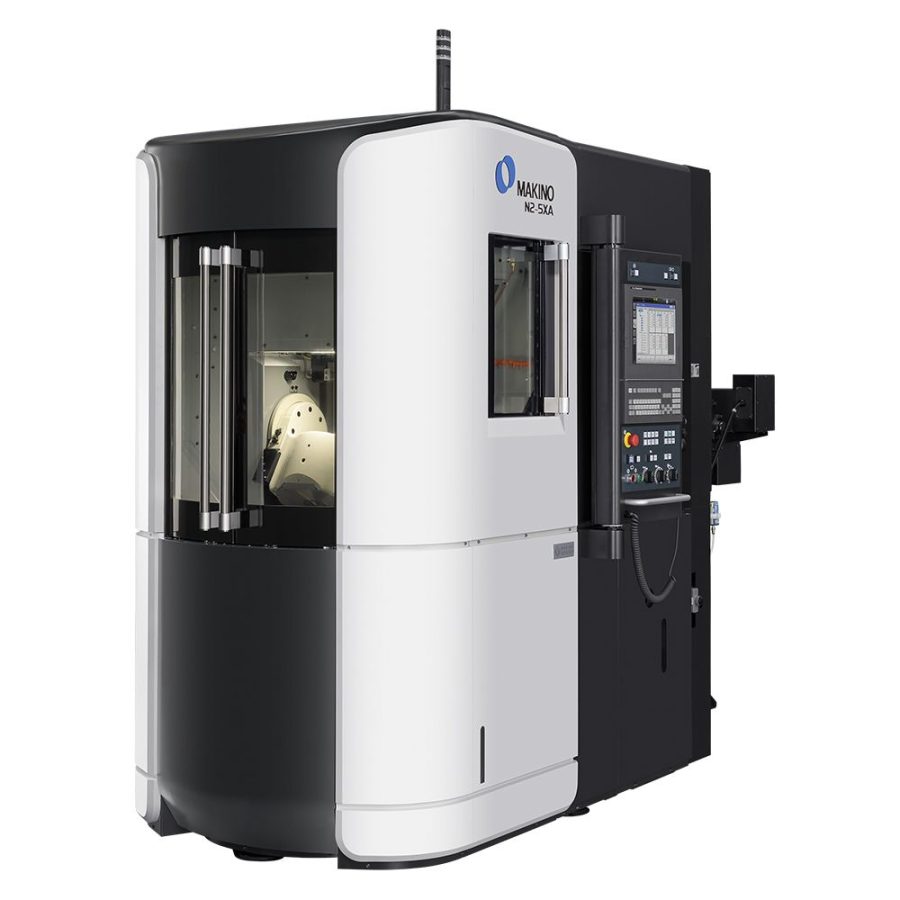

Technical Specifications

Pallet: 200 mm ø

X: 300 mm Y: 300 mm Z: 230 mm

It’s twin direct-drive rotary axes are housed in a rigid trunion casting, providing ideal accessibility to the workpiece and opportunities to improve quality and throughput by consolidating operations.

The N2-5XA features a 20,000 rpm HSK-40A spindle that accelerates to maximum RPM in just 0.8 seconds. This spindle works in concert with the standard AI Contour Control and 1.4G Z-axis acceleration to quickly and accurately produce the complex geometries common in medical implant components. Consuming a mere 26 square-feet of floor space, the N2-5XA is a high-productivity “right-sized” solution to your small part manufacturing challenges.