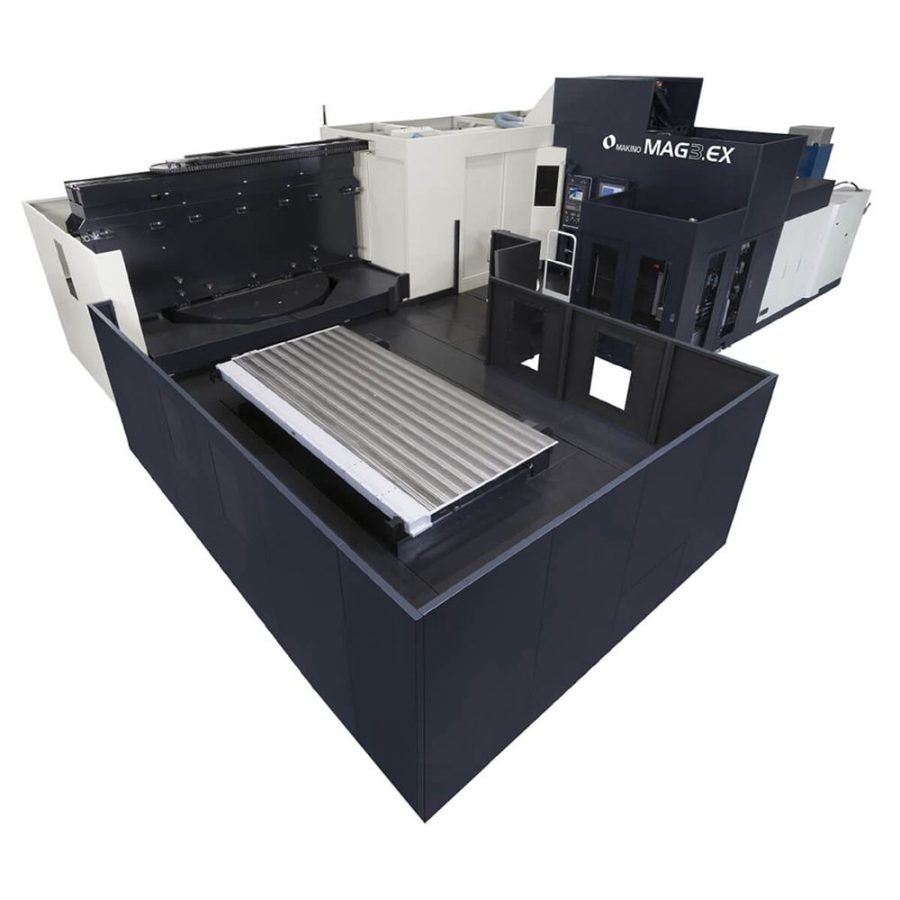

Technical Specifications

Pallet:

3,500 x 1,500 mm

X: 4,000 mm Y: 1,500 mm Z: 1,000 mm

A Axis

± 110°

B Axis

None

C Axis

360°

Spindle RPM

33,000 rpm – 130 kW

Rapid Traverse

X: 62,700 mm/min Y&Z 58,000 mm/min

Cutting Feedrate

50,000 mm/min

Maximum Workpiece

4,000 x 1,500 x 750 mm

Maximum Payload

3,000 kg

ATC Capacity

120 (180)

Tool to Tool

10 sec

Chip to Chip

15 sec

Maximum Tool Diameter

100 mm

Maximum Tool Weight

8 kg