Technical Specifications

Table: Rotary Table – A: 360º / B: ±140º

X: 370 mm Y: 270 mm Z: 750 mm

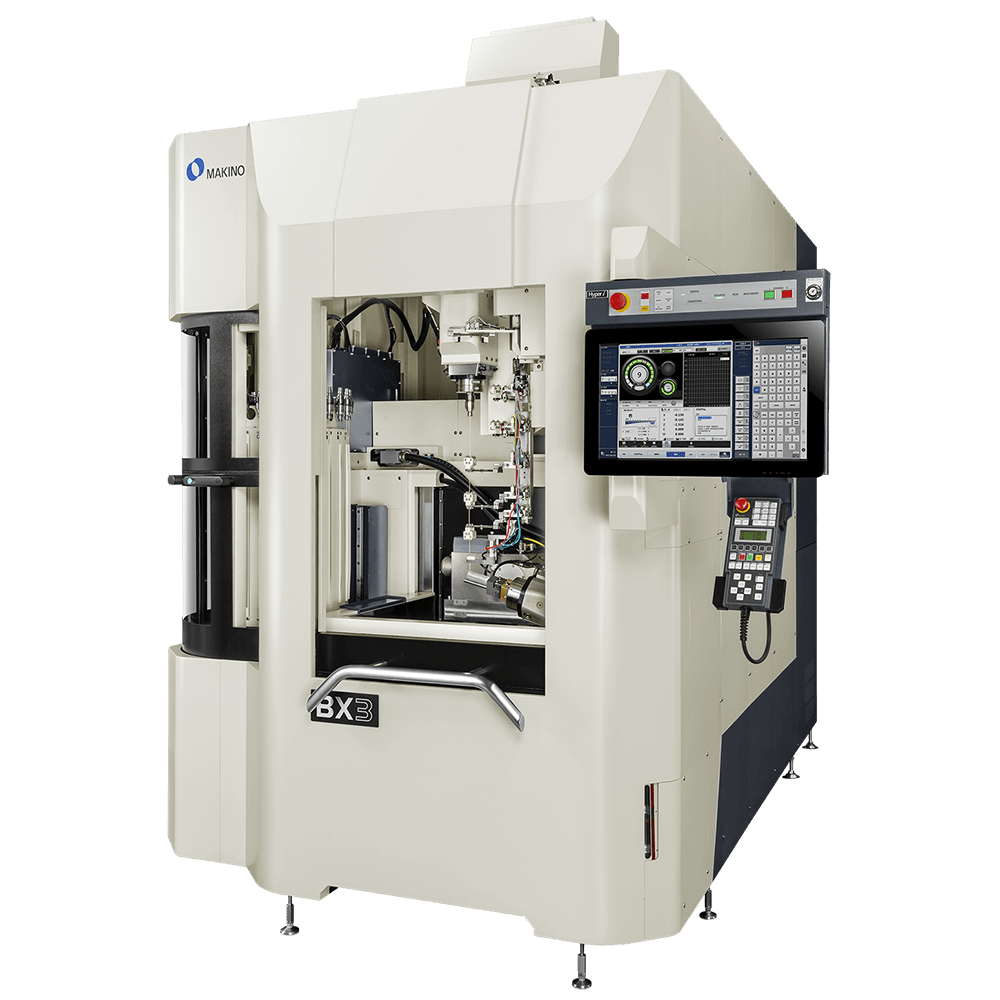

The BX3 uses Makino’s fully digital ES200A generator that provides faster machining speeds with an increase in power of up to 100 Peak Amps to boost productivity. The machine features fully submerged operations using a programmable rise and fall work tank to enhance machining speed and accuracy, as submerged operation is a critical element for stable breaking through machining. The advanced adaptive control of the ES200A generator is capable of detecting break through within 1 second, which is especially important when machining into hollow internal cavities.

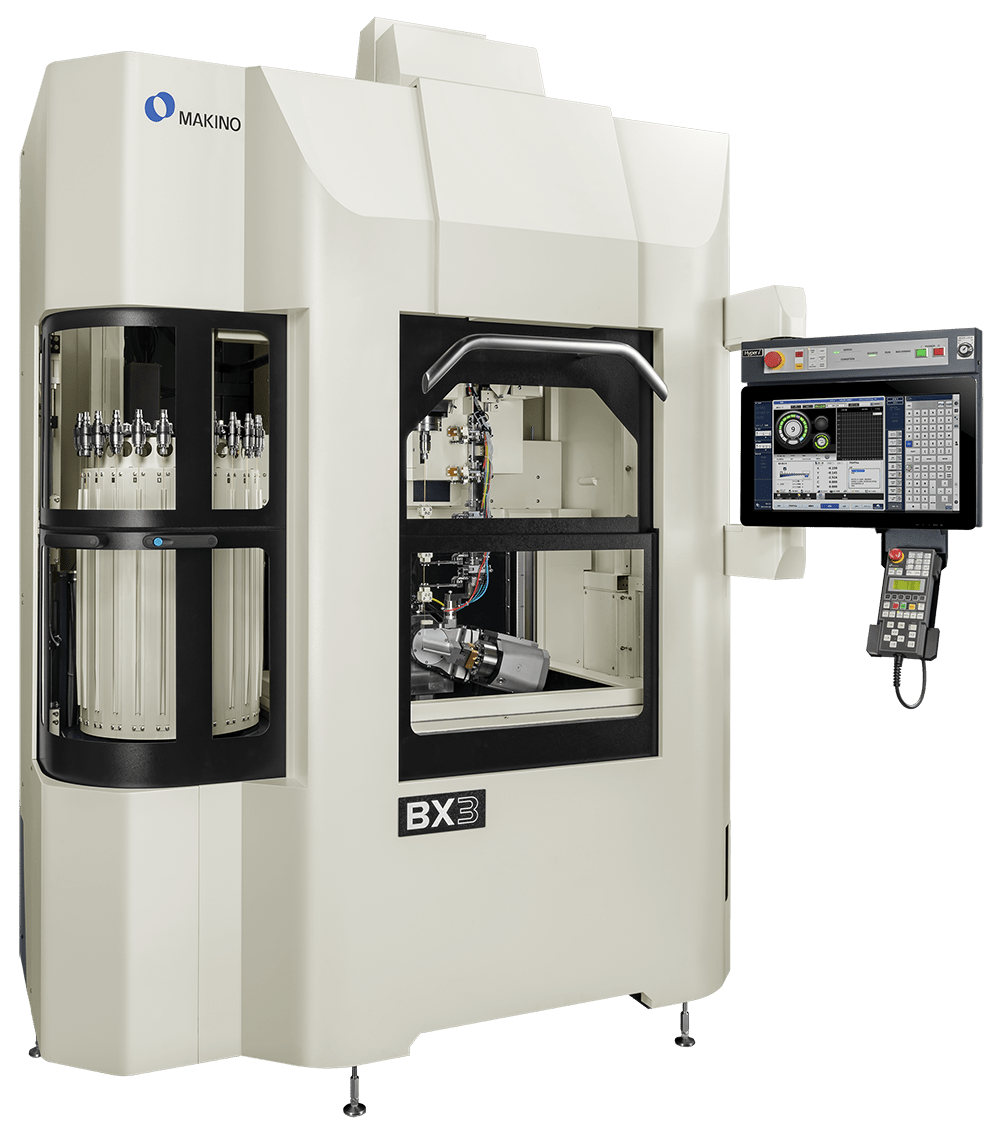

To improve process efficiency and the overall tact time, the BX3 machine has increased the rapid positioning rates to 10-meters-per minute, and the integral 2-Axis rotary table positioning rates to 10rpm to minimize the impact of machine movement during operation. The rotary table configuration has been optimized so that the typical size Aero-Engine detail sits close to the center of rotation, which minimizes the needed X/Y positioning distance. The BX3 is equipped with a 24 station ATC (Automatic Tool Change) unit that allows the use of fully supported electrodes up to 700mm (27.6”) long, and the simplified Electrode Tool Holders allow ATC exchanges to be performed faster and without having to move or drain the work tank, saving valuable process time.

The BX3 is standard with a full CE enclosure for added safety, and maintenance access has been centralized to the rear of the machine to minimize the total floor space requirement of multiple machine installations. The BX3 is configured with a 10MPa (1450 psi) diaphragm high pressure pump, and includes its own water filtration and de-ionization systems that are digitally monitored and integrated into the machine control. The machine utilizes the revolutionary Hyper-i control that features a large 24” class HD touch screen that operates like a common smart-phone or tablet that delivers a common interface used on all Makino EDM machines. The Hyper-i control contains many helpful user-friendly advanced functions that support the needs of the operator, including several specialized functions dedicated to EDM Drilling operations. The BX3 is standard with the HyperConnect IIoT network connectivity function for remote machine monitoring and interconnectivity of all manufacturing information.